Starclean saves clients time and money by reducing conveyor downtime, wasted material, manual handling, clean-up time, dust emissions, and health and safety concerns associated with material carryback.

Manufactured by Schulte Strathaus, one of Europe’s most respected belt cleaner manufacturers, Starclean incorporates the ingenious twist-swing tensioning mechanism. This ensures optimal blade contact to the belt, regardless of individual segment wear, for excellent cleaning performance, minimal maintenance and cost effective operation.

The simplicity of the unique quick-release tensioning devices and quick-change, slot-in blade design means site staff can quickly and safely carry out tool-less maintenance. It literally takes seconds to disengage, maintain and re-tension, keeping maintenance costs and downtime to a minimum.

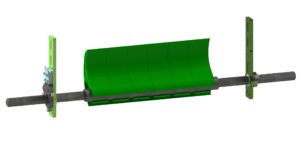

A primary position pre-cleaner which is highly effective at removing carryback from the conveyor belt, particularly in applications conveying high tonnages, wet and coarse material. Typically fitted at the ‘on head’ position of the head pulley, the system utilises specially formulated, belt friendly, polyurethane blades that adapt to the belt surface – even after wear.

A primary position cleaner which is extremely effective at removing fines and moisture from the belt. This cleaner is typically fitted at the ‘on head’ position of the head pulley and provides an alternative to ‘under belt’ secondary cleaners where space limitations impede installation. Abrasion resistant tungsten carbide blades ensure maximum cleaning performance and minimal adjustment.

The Starclean secondary scraper provides the benchmark for high efficiency removal of fines and moisture, offering the highest levels of conveyor cleaning performance. This cleaner is typically fitted in the ‘under belt’ position on or behind the nip point. Abrasion resistant tungsten carbide blades ensure maximum cleaning performance and minimal adjustment.

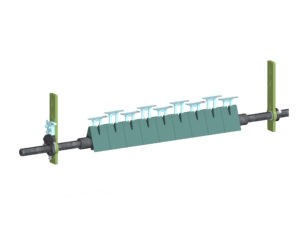

The Starclean chevron cleaner provides a good level of cleaning in a traditionally challenging application. This secondary position cleaner is fitted in the ‘under belt’ position on the return strand just after the head pulley. The 900 chevron series is a low cost, reliable alternative to other technologies, such as brush cleaners or air knife systems. The single piece blade is manufactured from wear resistant polyurethane which is formed into flexible fingers, cleaning deep into the cleats of the belt for maximum effectiveness.

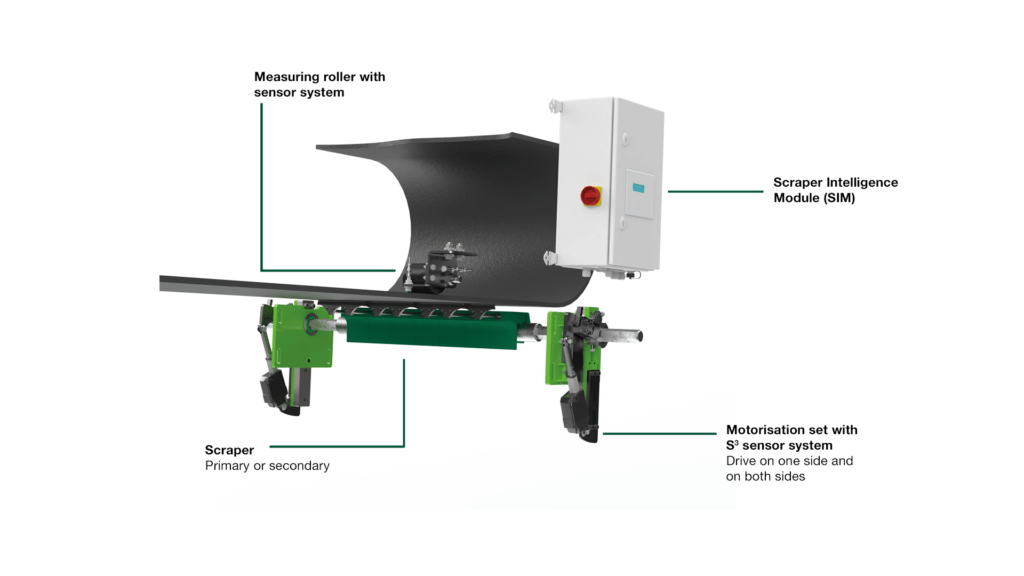

The unique smart scraper with an electric drive, combined with smart cloud dashboard, enables predictive maintenance of wear elements through preventive damage detection on the conveyor belt. This digital innovation gives the scraper the ability to self-regulate wear and tear while also ensuring a constant pretensioning force – completely automatically.

Designed according to the principle of “detect – react – protect”, this innovation enables continuous contact-based inspection of the conveyor belt, thus enabling predictive maintenance.

ProSpare, and its Bulk Materials team, have been named winner for an outstanding health and safety improvement at the Mineral Products Association (MPA) Health and Safety Awards 2024 – with STARCLEAN® belt cleaners picking up the award for the success at an Express Asphalt plant.

ProSpare’s installation of a STARCLEAN® scraper nullified a significant carryback problem experienced on the site’s main incline conveyor. The site previously had to clean-up piles of carryback from under the conveyor on a daily basis. Since installing STARCLEAN®, housekeeping requirements are now at a now a bare minimum, with the site team estimating a saving of 350 hours of material clean-up and 72 hours of maintenance over three years under the single conveyor.

*Disclaimer - ProSpare does not warrant that any Goods will be suitable for any particular purpose of the Customer, whether or not that purpose has been made known by the Customer to the Company. The Customer assumes all risk and liability resulting from the use of the Goods and it is the Customer’s responsibility for compliance for any specific application.

STARCLEAN® has cut carryback by 80% under one conveyor for a Sibelco glass recycling facility.

A leading national building material supplier was having maintenance issues with their belt conveyor at one of their asphalt plants. Starclean saved them over 400+ hours of cleaning and maintenance time.

National waste management experts, Biffa, saves 1 hour cleaning and eliminates 16 wheelbarrows of waste per week with STARCLEAN® at Leicester plant.

Working with one of the UK’s largest Limestone Quarries to improve the performance of belt conveyors - using Starclean, Centrax & Spill-Ex