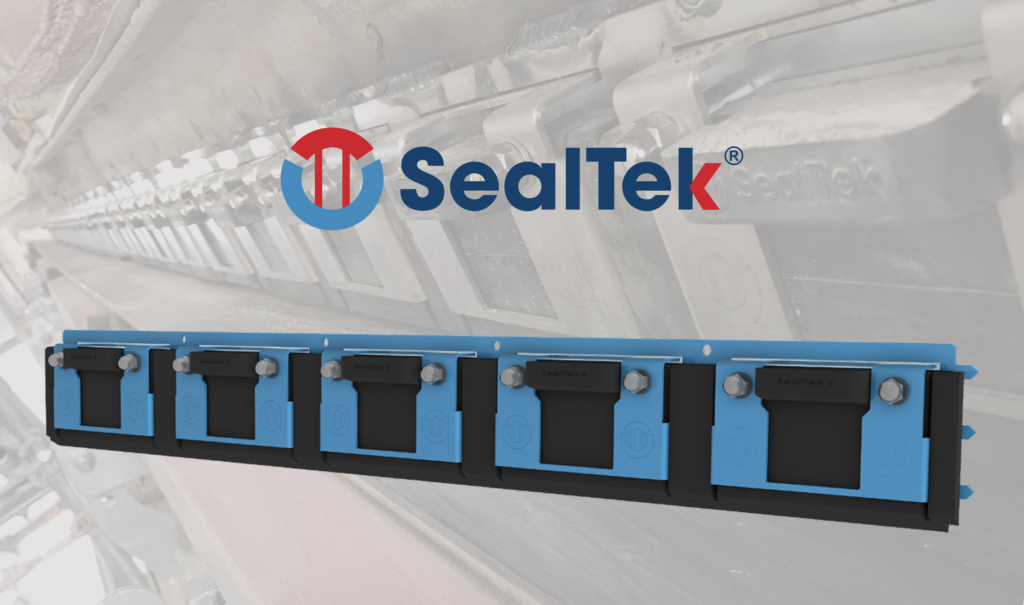

Having solved conveyor sealing problems for decades. The manufacturers of Spill-Ex, TBK Group, continue to develop their product range. They have taken yet another step forward in sealing technology with SealTek, which offers next level sealing whilst being even simpler to maintain.

Material spillage and dust emission from belt conveyors at transfer/loading points is commonplace on plants across the country. This problem creates a hot-spot for maintenance and a source of regular housekeeping for clean-up.

Ensuring your belt is clean and properly tracked will eliminate a wide range of problems on the conveyor, but it is critical to ensure that the belt is properly sealed. Poor sealing at transfer points can result in:

• Costly material spillage

• Regular clean-up requirements by site operatives

• Frequent unplanned maintenance

• Increased wear and damage to conveyor belt and conveyor components

• A poor working environment and increased risk to site operatives.

Many sealing solutions are available, but they often struggle to provide a consistent seal to the belt due to a number of factors. The forces encountered when loading can overwhelm the seal and force material outwards. The uneven nature of the belt profile, for example between rollers, can also result in gaps between the seal and belt occurring.

Using an appropriate belt support system, such as an Impact Bed, and our Spill-Ex skirt sealing system in tandem has significantly helped to minimise this problem. Spill-Ex utilises independently adjustable rubber blocks to create an effective seal against the profile of the belt. Having solved sealing problems for decades, the manufacturers of Spill-Ex, TBK Group, continue to develop their product range. They have taken yet another step forward in sealing technology with SealTek, which offers next level sealing whilst being even simpler to maintain.

SealTek builds upon the best features of the Spill-Ex skirting system to provide the next level of sealing technology for transfer points. It offers an exceptional seal to the belt and provides the simplest of maintenance, ensuring minimal spillage and dust emission over the long term.

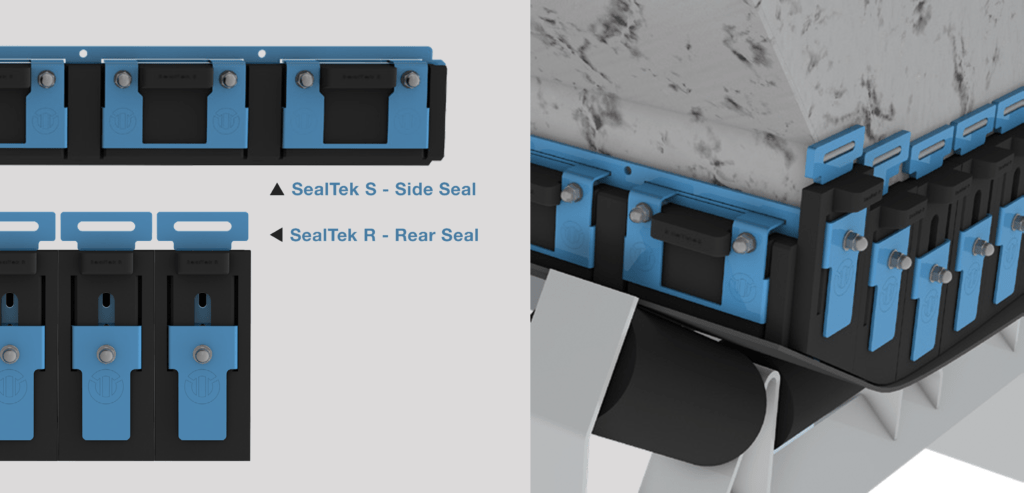

SealTek is modular and can be used to fully seal the transfer point, with options for both the side and rear. The SealTek S side seal comes in 1000mm lengths for quick installation. The rear SealTek R option is mounted as individual 100mm wide segments to best fit the real profile of the chute and belt.

At the heart of SealTek is its patented sealing arrangement. Collectively, the blocks form a continuous seal, yet they can still be individually adjusted and replaced with ease. The rubber blocks on a length of SealTek S all interlock and overlap, eliminating areas in which material can escape. The steel backing plate is also designed to dovetail with additional lengths of SealTek S. This ensures a consistent and continual seal throughout the transfer point and protects the rubber blocks from excessive material pressure.

With a protective mild steel or optional wear-resistant steel backing plate, SealTek S can be simply welded or fastened into place. Assembly is made even easier due to the interlocking nature of the backing plates.

The rubber sealing blocks are held in place with clever serrated clamps. These clamps ensure that the blocks cannot be pushed out of place or rotated, but allow for adjustment down to belt surface without the need to unfasten the clamp. Simply, the rubber blocks can be knocked down to the correct level by tapping the head with a suitable hammer.

The new design also maximises the service life of the components to reduce whole life costs. The SealTek S blocks can be adjusted down by 60mm, over 50% of the block compound, resulting in long-life and minimal product waste.

SealTek joins Spill-Ex in our range of high-performance conveyor sealing systems, and adds to our leading range of problem-solving conveyor components. Get in touch with the Bulk Materials Handling team to find out more or to arrange a site visit.

Bigger, better, and state-of-the-art! A behind the scenes look at the construction of the Castlewood building, and a tour around the completed offices and warehouse.